Product Description:

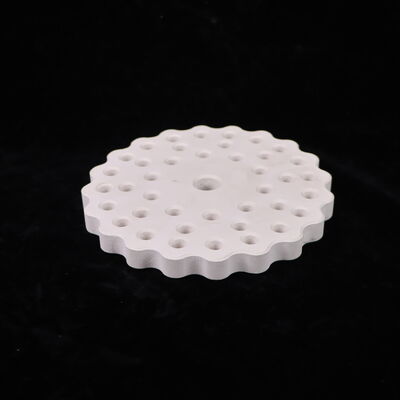

The Advanced Mullite Ceramic Material is a high-performance ceramic product renowned for its exceptional thermal and mechanical properties. Originating from China, this High Temperature Mullite Ceramic is engineered to meet the demanding requirements of various industrial applications where thermal stability, durability, and electrical insulation are critical. With a carefully controlled composition and manufacturing process, this advanced material exhibits a thermal expansion coefficient ranging from 4.5 to 5.5 × 10⁻⁶ /K, making it highly resistant to thermal shock and dimensional changes during rapid temperature fluctuations.

One of the standout features of this Advanced Mullite Ceramic Material is its low porosity, typically less than 15%. This low porosity ensures superior mechanical strength and resistance to wear and corrosion, enhancing the overall longevity of components made from this ceramic. The dense microstructure contributes to its excellent thermal insulation properties, while also providing a robust barrier against chemical attack in harsh environments.

The density of this High Temperature Mullite Ceramic ranges between 3.1 and 3.2 g/cm³, reflecting its compact and sturdy nature. This density range is indicative of a well-sintered ceramic body that offers optimal strength without compromising weight, making it suitable for applications where both durability and weight are considerations. The material’s density also plays a crucial role in its thermal conductivity and mechanical resilience, ensuring reliable performance under extreme conditions.

In addition to its mechanical and thermal properties, this Advanced Mullite Ceramic Material exhibits an impressive dielectric constant of 6 to 7. This moderate dielectric constant highlights its effectiveness as an electrical insulator, making it ideal for use in electronic and electrical components that require stable insulation properties over a wide temperature range. The combination of low dielectric constant and high thermal stability positions this ceramic as a preferred choice in applications such as substrates, insulators, and other electronic packaging materials.

Manufactured with precision and advanced ceramic processing techniques in China, this High Temperature Mullite Ceramic is consistently produced to meet stringent quality standards. The advanced processing ensures uniformity in composition, microstructure, and performance characteristics, making it a reliable material for engineers and designers seeking to optimize the performance of high-temperature systems.

Applications of this Advanced Mullite Ceramic Material are extensive and varied. It is widely used in furnace components, kiln furniture, heat exchangers, and thermal insulation parts due to its ability to withstand high temperatures without deformation. Its electrical insulating capability also opens doors to use in high-frequency electronic devices, semiconductor manufacturing, and other advanced technological fields. Furthermore, its resistance to chemical corrosion and thermal shock makes it suitable for use in harsh chemical environments and rapid heating or cooling cycles.

Overall, this Advanced Mullite Ceramic Material from China combines a low thermal expansion coefficient, low porosity, optimal density, and favorable dielectric properties to deliver a superior ceramic solution for high-temperature and high-performance applications. Its balanced properties ensure longevity, reliability, and efficiency, making it a key material in the advancement of ceramic technology and industrial applications where conventional materials fail to meet the demanding conditions. Whether for thermal management, electrical insulation, or structural components, this High Temperature Mullite Ceramic stands out as a premium choice for innovation and durability.

Features:

- Product Name: Engineered Mullite Ceramic Material

- Working Temperature: Up to 1400℃, suitable for high temperature applications

- Material Composition: High Temperature Mullite Ceramic

- Mechanical Strength: Ranges between 200 - 300 MPa, ensuring durability and reliability

- Porosity: Typically less than 15%, providing excellent structural integrity

- Melting Point: Between 1840 - 1850 °C, highlighting its thermal stability

- Advanced Mullite Ceramic Material designed for superior performance in extreme environments

Technical Parameters:

| Material |

Mullite Ceramic |

| Origin |

China |

| Thermal Expansion Coefficient |

4.5 - 5.5 × 10⁻⁶ /K |

| Thermal Conductivity |

3.5 - 4.5 W/m·K |

| Thermal Shock Resistance |

250 |

| Dielectric Constant |

6 - 7 |

| Porosity |

Typically <15% |

| Mechanical Strength |

200 - 300 MPa |

| Color |

White To Light Brown |

| Density |

3.1 - 3.2 G/cm³ |

Applications:

The KAMTAI MOLAISHITAOCI Mullite Ceramic product, originating from CHINA and certified with ISO 9001, is an advanced mullite ceramic material designed to meet the rigorous demands of various industrial applications. This engineered mullite ceramic material boasts a unique combination of properties, making it ideal for use as a mullite ceramic thermal insulator in high-temperature environments. Its exceptional thermal shock resistance of 250 and mechanical strength ranging from 200 to 300 MPa ensure durability and reliability under extreme conditions.

Due to its superior dielectric constant of 6 - 7, the KAMTAI mullite ceramic is well-suited for applications requiring excellent electrical insulation and stability. Its color ranges from white to light brown, reflecting the purity and quality of the material. This product is perfect for use in industries such as electronics, metallurgy, aerospace, and automotive manufacturing, where thermal insulation and mechanical robustness are critical.

The advanced mullite ceramic material is frequently used in furnace components, kiln linings, and heating elements, where it acts as a thermal insulator to improve energy efficiency and protect sensitive components from heat damage. It is also applied in electronic substrates and insulators, where its dielectric properties enhance performance and safety. The engineered mullite ceramic material's ability to withstand thermal shock makes it suitable for repeated heating and cooling cycles without degradation.

The product is supplied in wooden box packaging to ensure safe transportation and storage, with a minimum order quantity of 1000PCS. KAMTAI offers a supply ability of 500,000PCS per month, making it an excellent choice for large-scale industrial needs. The delivery time is 30 days after payment, with payment terms via TT, and pricing is negotiable to accommodate various project budgets.

Overall, the KAMTAI MOLAISHITAOCI mullite ceramic product is a reliable solution for applications demanding high-performance thermal insulation and mechanical strength. Whether used as a mullite ceramic thermal insulator in industrial furnaces or as a critical component in electronic devices, this advanced mullite ceramic material ensures long-lasting performance and efficiency.

Customization:

KAMTAI offers premium Engineered Mullite Ceramic Material under the model number MOLAISHITAOCI, originating from CHINA. Our Mullite Ceramic Thermal Insulator products are certified with ISO 9001, ensuring top quality and reliability for high-performance applications.

We specialize in High Temperature Mullite Ceramic products with outstanding mechanical strength ranging from 200 to 300 MPa, a dielectric constant of 6 - 7, and a thermal expansion coefficient between 4.5 - 5.5 × 10⁻⁶ /K. The porosity is typically less than 15%, contributing to excellent thermal insulation properties.

The product color varies from white to light brown, and each order is packaged securely in a wooden box to maintain product integrity during shipment. Our supply ability reaches up to 500,000 PCS per month, with a minimum order quantity of 1000 PCS.

Pricing is negotiable to meet your specific needs, with delivery time guaranteed within 30 days after payment. Payment terms are TT, providing a flexible and secure transaction process.

Choose KAMTAI for reliable and customizable mullite ceramic solutions tailored to your industrial requirements.

Ваше сообщение должно содержать от 20 до 3000 символов!

Ваше сообщение должно содержать от 20 до 3000 символов! Пожалуйста, проверьте свою электронную почту!

Пожалуйста, проверьте свою электронную почту!  Ваше сообщение должно содержать от 20 до 3000 символов!

Ваше сообщение должно содержать от 20 до 3000 символов! Пожалуйста, проверьте свою электронную почту!

Пожалуйста, проверьте свою электронную почту!